Description

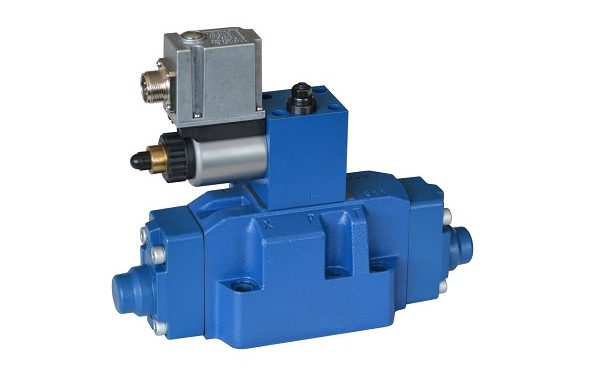

Rexroth 4WRKE16W8-125L-3X/6EG24EK31/F1D3M R900751112 Proportional directional control valve

Bosch Rexroth 4WRKE16W8-125L-3X/6EG24EK31/F1D3M Product Information and Introduction

Product Information:

1. Model: 4WRKE16W8-125L-3X/6EG24EK31/F1D3M

2. Product Type: Proportional directional control valve, pilot-operated, with integrated electronics

3. Integrated Electronics: With integrated electronics

4. Nominal Size: 16

5. Valve Ports: According to ISO 4401, code: 4401-05-04-0-94

6. Spool: Type W8, overlap and open area ratio 2:1 (A:B), similar to W6 spool

7. Flow: 125 L/min, pressure drop Δp = 10 bar

8. Characteristics: Linear

9. Series: 30 to 39 series

10. Pilot Control: Proportional solenoid, detachable coil

11. Voltage: 24V DC

12. Pilot Oil Supply: External pilot oil supply and return

13. Electrical Interface: According to DIN EN 175201-804 connector, without mating connector (to be ordered separately)

14. Control Signal Input: 4 … 20 mA

15. Pilot Valve: With pressure relief valve ZDR 6 DP0-4X/40YM-W80 (fixed setting)

16. Seals: NBR seals, suitable for mineral oils (HL, HLP)

Product Introduction:

1. This is a 2-stage proportional directional control valve for controlling the flow and direction of fluids.

2. The main stage uses closed-loop position control, with the spool position independent of the larger fluid power forces.

3. The main components include the pilot control valve, body, main spool, cover, centering spring, inductive position sensor, and pressure reducing valve.

4. The control principle is that the main spool position is compared to the control value through the inductive position sensor connected to the integrated electronics. Any potential control deviation is identified, and current is applied to the proportional solenoid of the pilot valve, moving the pilot spool and thereby the main spool to change the flow.

5. The main spool is forced-balanced in the closed-loop control position, maintaining the actual value equal to the control value.

6. The spool stroke and control opening change proportionally to the control value.

7. The integrated electronics are integrated into the valve, and by matching the valve and electronics, the number of valve types is minimized.

8. A back-pressure valve should be installed to prevent the tank line from draining.